From a study conducted by British universities comes SWEET, a sustainable and biodegradable electronic fabric: innovative materials and inkjet printing guarantee efficiency and reduced ecological impact

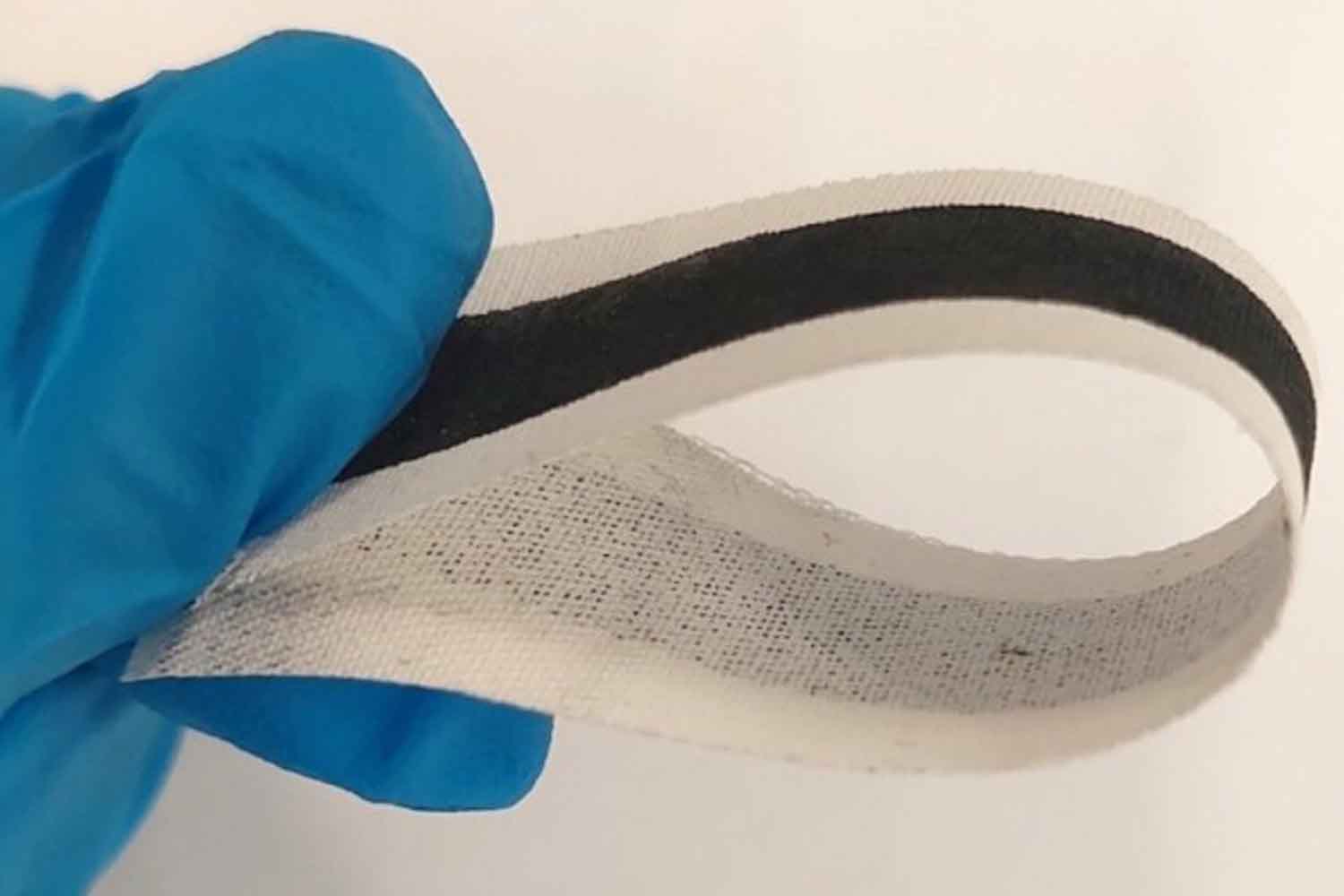

©Marzia Dulal

A team of researchers from the University of Southampton and UWE Bristol has developed a groundbreaking technology to create biodegradable and eco-friendly electronic fabrics, potentially reshaping the future of fashion and wearable tech. The project, named SWEET (Smart, Wearable, and Eco-friendly Electronic Textiles), was recently detailed in the journal Energy and Environmental Materials.

What are e-textiles—and why do they matter?

Electronic textiles, or e-textiles, are fabrics embedded with electronic components like sensors, batteries, or LEDs. They’re widely used in fashion, sports, and healthcare, representing one of the most exciting frontiers in tech. But there’s a serious environmental downside: metallic components like silver don’t break down easily, making recycling a complex and often wasteful process.

“Integrating electronics into traditional fabrics makes recycling difficult and increases environmental impact. We’ve developed a way to let these materials decompose naturally at the end of their life cycle.”

— Professor Nazmul Karim, University of Southampton

Inside project SWEET: a high-tech, low-impact textile

The magic of SWEET lies in its three-layer structure:

-

A sensing layer that collects data

-

A middle layer connecting the sensors

-

A Tencel base layer, a biodegradable fabric made from wood pulp

The active layers—made of graphene and PEDOT:PSS, a conductive polymer—are printed directly onto the textile using inkjet technology. This approach allows precise material deposition, cutting waste, water usage, and energy consumption compared to conventional printing.

Tested on real people—and in the dirt

The researchers tested their fabric on five volunteers, using sensor-equipped gloves to monitor heart rate and body temperature. The results? Surprisingly accurate, meeting the standards used in the medical field.

To check biodegradability, the team buried fabric samples in soil. After just four months, the textile had lost nearly 50% of its weight and 98% of its strength.

“Our graphene-based electronic textiles have up to 40 times less environmental impact compared to conventional electrodes. That makes them a far more sustainable option.”

— Marzia Dulal, lead author of the study

Cleaner production, smarter clothes

The SWEET fabric also dramatically reduces the footprint of production. Inkjet printing uses fewer resources and produces virtually no waste—a major win for the fashion industry, long criticized for its heavy pollution.

By offering a viable solution to combine advanced tech with sustainability, SWEET represents a potential breakthrough in addressing some of today’s most urgent challenges.

“Our next goal is to create full garments capable of monitoring health and preventing diseases like cardiovascular conditions.”

— Professor Nazmul Karim

Science is lighting a new path forward: wearing technology doesn’t have to cost the Earth.

Source: Energy & Environmental Materials