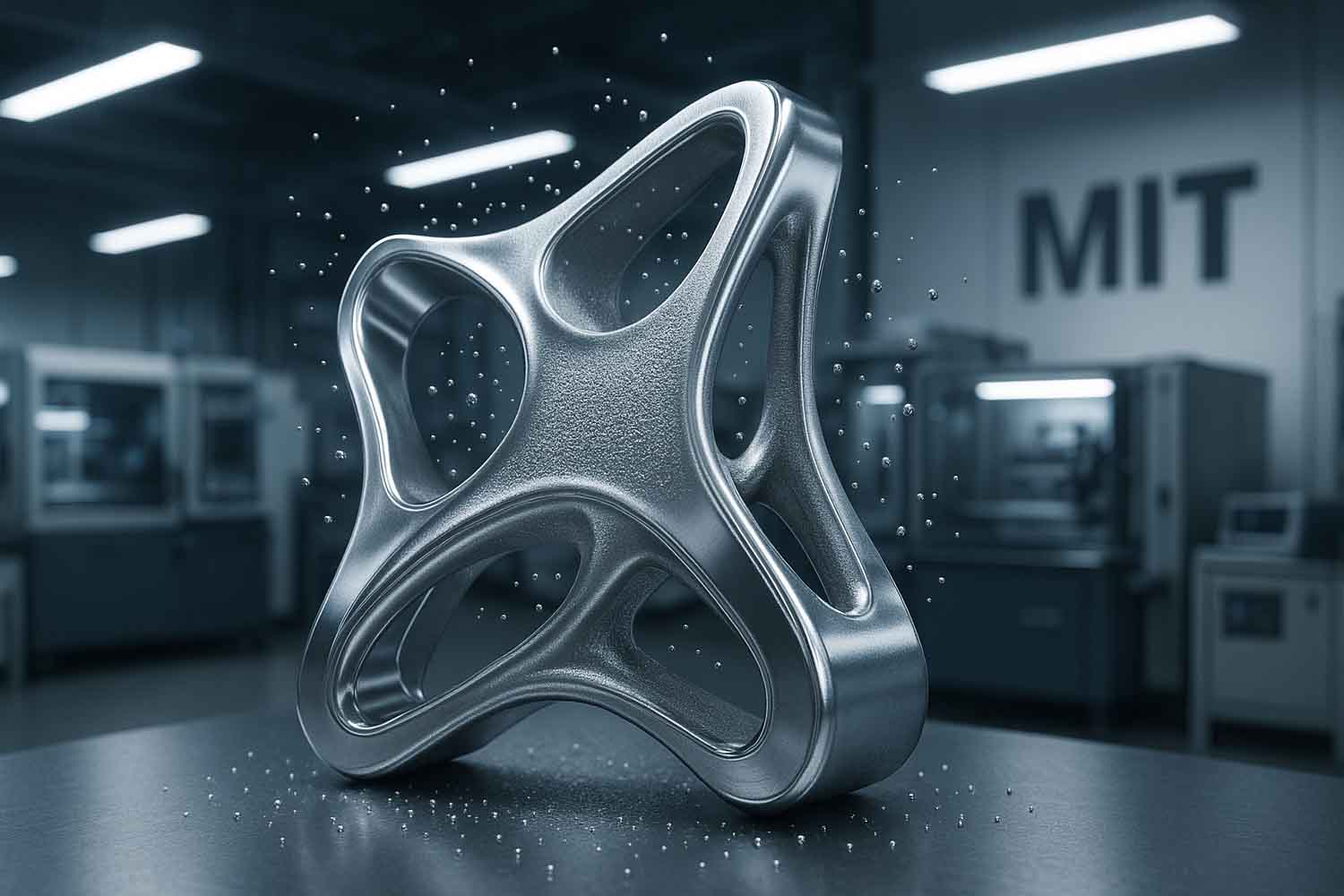

MIT researchers have developed a new industry ally: an advanced aluminum, 3D printable, five times stronger than traditional material

Table of contents

A team from the Massachusetts Institute of Technology (MIT) has made an enormous leap forward in the field of metallurgy, designing a new type of aluminum with exceptional performance. This innovative material, the result of collaboration between artificial intelligence and the most advanced engineering techniques, is capable of withstanding temperatures up to 752°F (400°C) and exhibits mechanical strength five times greater than conventional aluminum. It could radically transform strategic sectors such as aeronautics, automotive, and the space industry.

Artificial intelligence and simulations serving materials science

At the heart of this revolution lies a pioneering method that leverages artificial intelligence to select the most promising composition among dozens of variants of metal alloys. Researchers Mohadeseh Taheri-Mousavi, a postdoc at MIT, and Professor John Hart, director of the mechanical engineering department, combined advanced thermodynamic simulations and analysis through electron microscopy to design an optimal alloy.

This technique allowed them to control the distribution of particles at the nanometric level within the aluminum matrix, obtaining a stronger material without increasing weight. In practice, by regulating the size and positioning of particles, the team achieved a significant increase in mechanical strength while maintaining a lightweight and high-performance structure.

A new 3D printing technique

Another key element of MIT’s innovation is the adoption of a laser melting 3D printing technique, capable of rapidly solidifying molten metal. Unlike conventional methods that require post-production heat treatments, this process creates a material that is already high-performing immediately after printing.

This represents a fundamental technological leap: many metal alloys obtained through additive manufacturing require subsequent processing to reach good strength levels. The new MIT aluminum, however, is designed from the beginning to be 3D printed, reducing production times and costs without compromising quality.

The aluminum of the future for cars, aircraft, and space missions

The innovative composition of this aluminum is optimized to meet the needs of the most demanding sectors. In the aerospace field, where every gram counts, being able to use a lighter but stronger material could mean a reduction in structural weight of aircraft, greater engine efficiency, and decreased fuel consumption.

In the automotive sector, the new material can contribute to designing lighter frames, improving energy efficiency and lowering CO₂ emissions, without compromising vehicle safety. But it’s in the world of space technology that this alloy could truly make a difference: satellites, orbital modules, and critical components could be manufactured with this new alloy, making future missions more economical and more efficient.

Source: MIT