Japan’s SHI unveils a plasma-based process that slashes the cost and time of making perovskite solar cells, while Chinese researchers set new records for efficiency and durability.

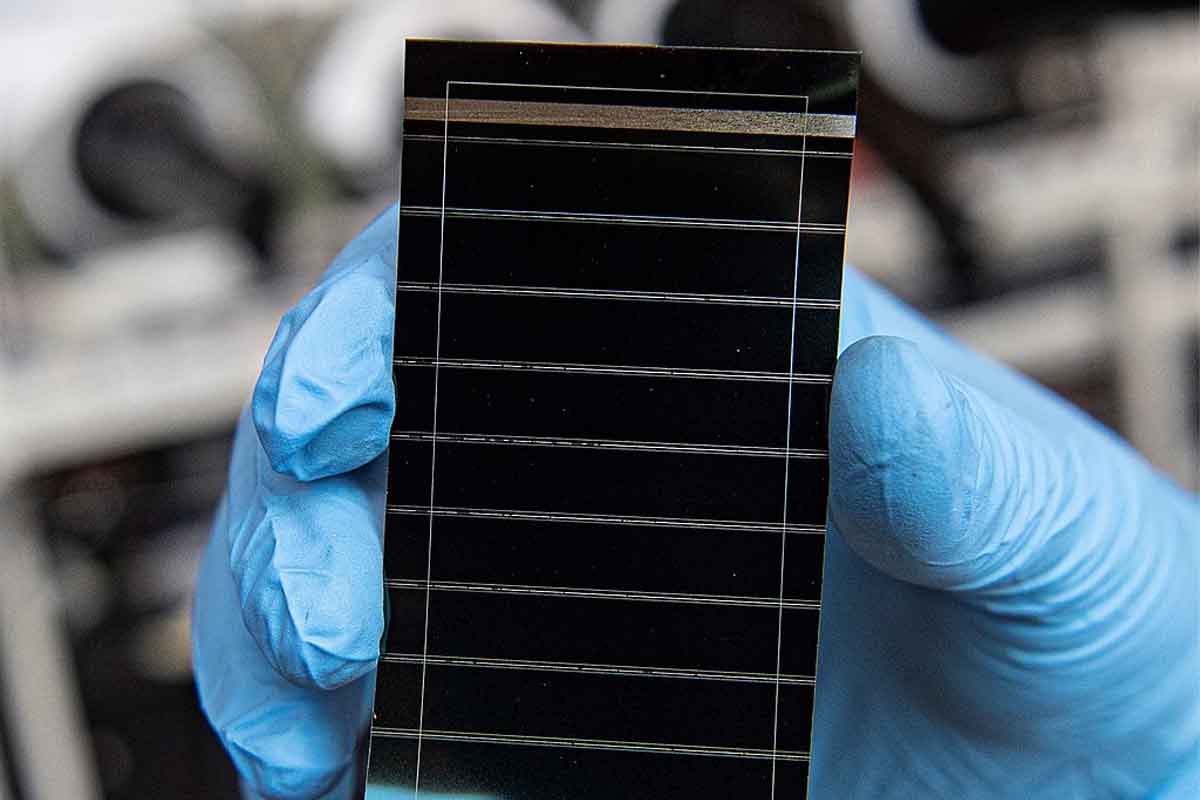

@Wikimedia Commons – Dennis Schroeder / National Renewable Energy Laboratory

A new technology from Japan may overcome one of the biggest hurdles holding back perovskite solar cells: scaling up production. Sumitomo Heavy Industries (SHI) has unveiled a breakthrough process known as Reactive Plasma Deposition (RPD), which promises to change the game.

With this method, solar cells can be made faster, at dramatically lower costs, and without toxic chemicals. For years, perovskites have been hailed as the next frontier in photovoltaics—light, flexible, and highly efficient—but they’ve mostly remained trapped in the lab. RPD could be the key to finally installing them on rooftops, façades, and even flexible surfaces.

How it works

At its core, RPD is an advanced version of physical vapor deposition (PVD), but it’s tailored to simplify one of the trickiest steps in making these cells: depositing the electron transport layer (ETL). That layer acts like a highway for electrons, guiding the energy captured from sunlight into the electrode so it can be harvested.

Traditional methods are far from ideal. They require very high temperatures, energetic particles, and often hazardous chemicals. All of these drive up costs, pose safety concerns, and can even damage the fragile perovskite material itself, which has a reputation for being unstable.

SHI’s solution instead uses a reactive plasma to lay down ultra-thin films of tin oxide (SnO₂) at low temperatures. This delicate touch preserves the perovskite’s structure while speeding up manufacturing. The numbers are striking: production becomes 200 times faster and costs can fall by as much as 99.5% compared with conventional technologies.

Cleaner, safer, and industry-ready

Speed and cost matter, but so does compatibility. RPD operates with non-toxic gases and works seamlessly with other key materials used in solar cells, including indium tin oxide (ITO), the standard for transparent electrodes.

That compatibility means manufacturers could produce solar modules continuously, on a large industrial scale, instead of halting for complex treatments. In other words, this isn’t just a lab innovation—it’s potentially ready for a factory line.

Japan has set an ambitious target: 20 gigawatts of installed perovskite capacity by 2040, especially in cities where flexible, building-integrated panels could shine. SHI is already moving forward. In 2025, the company began testing ultra-thin modules and tandem perovskite-silicon cells, hitting a record 26.5% efficiency.

A record-breaking inverted cell from china

Meanwhile, China is pushing the limits of research. A team at Xi’an Jiaotong University developed a record-setting inverted perovskite solar cell, certified at 26.08% efficiency. Their trick was using a self-assembled bilayer (SAB) made of phosphonic acid and triphenylamine.

Unlike the classic n-i-p configuration, their p-i-n design provides greater thermal and mechanical stability. Lab tests showed the cell kept 94% of its original efficiency after 2,000 hours under heat and humidity—roughly 185°F (85°C)—a benchmark that surpasses commercial silicon solar cells.

The study, published in Nature Energy and verified by the China National Accreditation Service, underscores a crucial truth: durability matters as much as raw efficiency. A cell that performs for decades in harsh conditions could be more valuable than one with a slightly higher peak output.

Chasing the next frontier: beyond 30% efficiency

The 26% milestone is impressive, but it’s hardly the finish line. Around the world, labs are racing to push efficiency higher. Ultrathin perovskite cells are already approaching 27%, thanks to optical resonators that trap and boost sunlight. Even more exciting are tandem cells, which stack perovskite on top of silicon. These have already broken the 30% efficiency barrier, hinting at a new era in photovoltaics.

Still, researchers caution against obsessing over efficiency alone. As one expert noted, what counts is not just how much power a cell can generate, but how long it can keep doing it. That’s why the Chinese innovation—pairing high efficiency with stability—is generating so much buzz. It points toward solar panels that can survive heat, humidity, and decades of wear without losing their edge.